During the last century, agriculture significantly transformed, as farms and the equipment needed to run them, grew ever larger and more technical. Meanwhile the demand to produce greater and greater yields increased sharply along with regulatory pressures on the agricultural practices that produce those yields.

According to the United States Department of Agriculture, the number of family farms in the United States has fallen from 6.8 million in 1938 to roughly two million today. The fastest growing segment of our nation’s farming population is now over 65 and within the next decade, the majority of American farmers will be retirees.

That is why it is so vitally important that the ‘next generation’ of farmers, who are interested in successfully pursuing a career in farming, become actively involved at an early age in their family’s operation so they are ready and able to assume the ‘reins’ from the previous generation when the time is appropriate, creating a more seamless transitionary period.

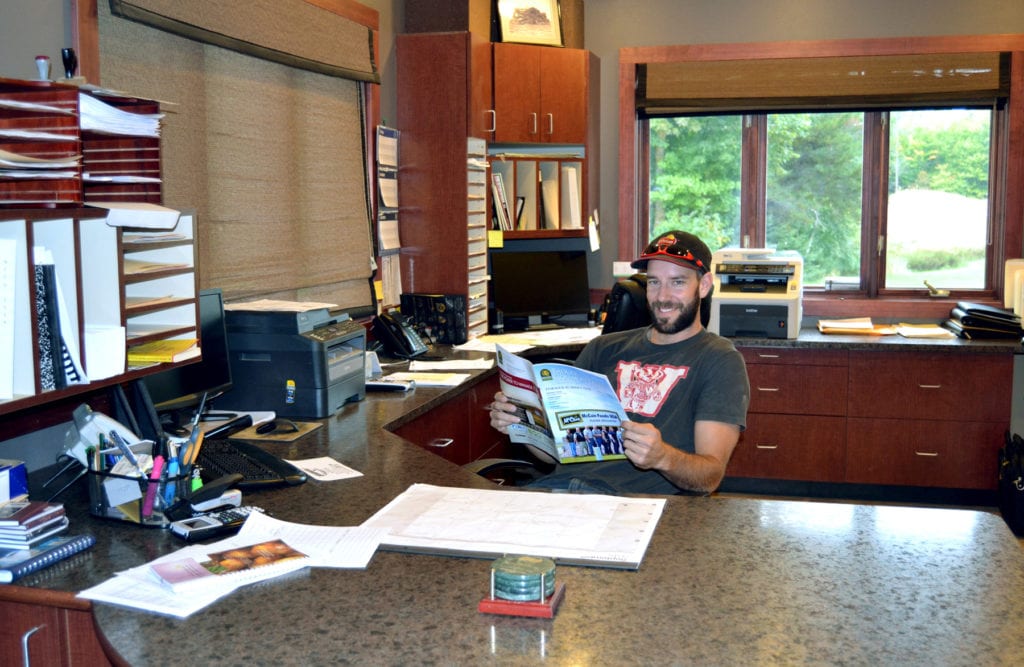

Eric Schroeder, son of Pete and Gina Schroeder of Schroeder Bros. Farms, Inc. and Assistant Farm Manager of the family operation, is a perfect representation of what these ‘next generation’ farmers represent: young men and women who have learned the practices and challenges of farming along with acquiring leadership and managerial skills.

A fifth generation member of his family farming operations, founded in Antigo in 1879, Eric is a strong participant in the organizations that support the farming industry. In 2014, Eric was awarded Young Grower of the Year by Wisconsin Potato & Vegetable Growers Association (WPVGA), in recognition of his leadership and active contribution to the potato industry.

Elected as the 2014 Potato Industry Leadership Institute’s Grower-Leader, Eric also serves on WPVGA’s and Wisconsin Seed Potato Improvement Association’s (WSPIA) board of directors, as well as a Wisconsin representative to the United States Potato Board (USPB). He chairs both the Regulatory Committee for the WSPIA and the Chip Committee for WPVGA.

The Schroeder family also owns and operates Schroeder’s Gifts in Antigo, WI (schroedersgifts.com).

Schroeder Bros. Farms, Inc. is one of the largest Frito-Lay seed producers in the U.S. and a four-time winner of Frito-Lay’s seed grower of the year award. Since Eric does the food safety audits and documenting for Frito Lay as a supplier, he is the ideal candidate for our interview for the November Seed issue. (Is this correct?)

Before we get into specifics of the operation, please share some of the history of Schroeder Bros. Farms, Inc. and your favorite memories of growing up and working on your family farm, since these things helped shape your love of agriculture.

The farm was originally homesteaded in 1879 in Antigo, WI. Initially it started out with a few dairy cows and a few crops to feed the animals and the family.

In the 1960s, my grandfather, John, came back to the farm after his brother, Tom, was in a serious snowmobile accident that left him unable to work on the farm. Shortly thereafter, Grandpa John began growing certified and foundation seed.

In the early 1980s, John T, Pete and Rob began returning to the farm and it has steadily grown into the farm it is today.

My earliest memories of the farm come from the days when they used to collect and cook their own maple syrup. Mom would bring Andy and me down to the sap house where we would drink fresh maple syrup from the tap.

Your operation is widespread, includes some outlying areas and covers a number of crops. Can you describe the configuration, your crop mix, soil types and the challenges you face when your land is not contiguous?

We farm in Langlade, Shawano and Oconto counties. Most of our crops are grown right around the Antigo flats and Bryant. We go as far north as Post Lake (35 miles) and as far east as Suring (45 miles).

The majority of our crop is in the Antigo flats, which is Antigo Silt Loam (Wisconsin‘s state soil by the way).

However, the outlying areas like Post Lake and Suring consist of sandier soils similar to soils in Pearson and as well. Farming these sandier soils allows us to start our spring planting earlier and provides us with options if we get heavy rains in the Antigo area during planting and harvest. That being said, sandy soils also require irrigation more often because they do not retain water like the silt loam does.

The biggest challenge of farming the outlying areas is getting the crop home. We need to run about 20 bulk trucks between the fields and storage consistently for 12 hours/ day. Between traffic, breakdowns and other obstacles, this is not always a smooth process. Depending on yield, sometimes the harvester can dig faster than we can transfer the potatoes into storage or vice versa, which creates timely delays.

Most of our fields are on a three-year rotation including two years of alfalfa, field corn, soybeans and oats.

How would you describe your role as Assistant Manager in the operation and particularly in regards to your responsibilities with your major client, Frito-Lay?

I am not really sure that I have a real title yet. My role on the farm varies every other week, it seems. During planting and harvest, I am out in the tractor. In summer, I could be out in the water truck filling the sprayers, or watering the crop in Suring. In the winter, I am in the office most of the time tracking, sending invoices and keeping up on the food safety program.

As for Frito-Lay, John T handles most of the responsibilities and direct communication with them. Between my cousin JD and me, we help with Frito-Lay’s crop tracking requirements.

What challenges do think young farmers face and how are these challenges different from those faced by previous generations?

For a young farmer, it can be a bit overwhelming at times even being in the same conversations with some of the more established growers who seem to have been doing this for a hundred years.

I have found that in the few short years that I have been involved in farming, there are a ton of intelligent, well-respected individuals in this business and it really is a pleasure to be a part of it.

I would say the biggest difference in challenges between generations is probably the higher regulations/restrictions today’s farmers face on pretty much everything.

How do you see the regulatory and legislative climate changing, particularly in regards to the growing pressure from environmental activists who wish to limit commercial farming?

Whether it involves water, pesticides, GMOs, animal husbandry, drones or the next ‘big’ thing, every day we seem to encounter a new challenge that we need to wrap our heads around so we can figure out how to deal with it.

Historically, farmers have been more concerned about simply growing and marketing their crops. You did not have to convince your friends and neighbors about the importance of what you were doing because it helped support the community. If the farmers were doing well, so was the local economy.

Nowadays, you have to be able to interpret complicated regulations, monitor legislative activities, understand the implications of those activities, promote your occupation to the public and keep them aware of all the good things farmers do. You also have to master new ecological and sustainable methods of farming while keeping abreast of new technologies and growing techniques.

Is it worth it? I think so but I also believe the future will only bring more challenges and it will be up to all of us growers to keep fighting for what we believe is right.

What steps has your operation taken to ensure a quality product for your clients as well as consumers.

We always put our clients first, which I think in turn, helps satisfy the end consumer as well.

We carefully focus on providing our clients with exactly what they need: the correct size profile, the right varieties and then the desired quantity of each variety.

We give our clients the option to pick up different varieties from both our locations, which allows them to get their seed quicker and more efficiently. Some clients ask us to precut seed for them, which we do our best to accommodate. Whether they buy 50 cwt or 50,000 cwt, we do everything we can to provide the best seed and service.

Technology is a major part of today’s farming environment. What are some of the technological advances your operation has adopted?

The most recent example of us keeping up with technology would be our purchase of two Odenberg FPS sorters and a Halo for the fresh pack shed.

The FPS sorter allows us to remove most of the foreign debris from the dry seed potatoes before it gets to the grading lines, allowing the graders to concentrate more fully on the quality of the tuber than on removing rocks and vines.

The Halo removes all foreign debris and defects to further reduce rejected loads and improve the overall quality. It also reduces over grading, which can cause good product to be discarded.

What would you recommend to other growers as far as getting involved with farmer organizations and associations?

Being involved in these types of organizations allows you to do several things especially as a young grower.

Participation in Wisconsin Potato & Vegetable Association (WPVGA), United States Potato Board (USPB) and National Potato Council (NPC) and Wisconsin Seed Potato Improvement Association (WSPIA) provides you with the opportunity to learn all the different levels and aspects of the potato business.

Most importantly, these organizations help educate you on the local, state, national and even worldwide issues that confront our industry. By absorbing the collective knowledge you are exposed to within these groups, you are better able to intelligently voice your opinion and represent your growing region, which is quite an honor.

As a Wisconsin Certified Seed grower, selling certified and foundation seed, how do you feel about Simplot’s new Innate™ potatoes and what do you think genetically modified potatoes might mean for the improvement of future potato breeding programs.

The next wave of potato breeding is both very intriguing yet simultaneously scary.

It is intriguing because these advances may greatly reduce the amount of inputs that go into growing a crop, whether they are pesticides, fertilizers or water.

I think everyone would agree that further reduction of pesticides is a good thing, but at the same time, it is scary because you do not really know how the public will react and what the ramifications will be to the whole industry.